Reverse logistics is the reverse of the standard supply chain flow, where goods move from manufacturer to end consumer. Reverse logistics includes activities like returns management, refurbishment, recycling, and disposal. It’s an important part of supply chain management, often involving the return of products due to damage, seasonal inventory, restock, salvage, recalls, or excess inventory.

What Is Reverse Logistics?

Reverse logistics is a type of supply chain management that moves goods from customers back to the sellers or manufacturers. Once a customer receives a product, processes such as returns or recycling require reverse logistics.

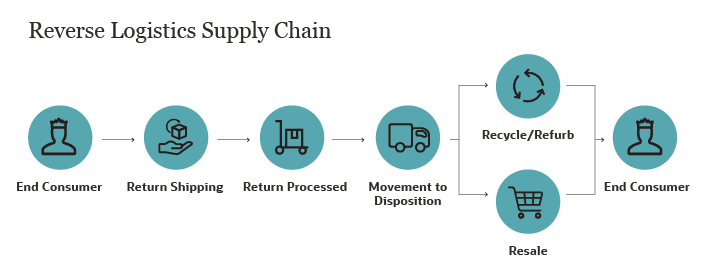

Reverse logistics start at the end consumer, moving backward through the supply chain to the distributor or from the distributor to the manufacturer. Reverse logistics can also include processes where the end consumer is responsible for the final disposal of the product, including recycling, refurbishing or resale.

Why Do Companies Use Reverse Logistics?

Organizations use reverse logistics when goods move from their destination back through the supply chain to the seller and potentially back to the suppliers.The goal is to regain value from the product or dispose of it. Per the IHL Group, worldwide returns amounted to $1.8 trillion in 2022 — a figure that more than doubled in less than a decade — and have become increasingly common with the growth of ecommerce. Indeed, ecommerce sales have a higher return rate, with 17.6% ($247 billion) of merchandise purchased online returned, compared to 10% ($371 billion) for brick-and-mortar sales, according to the National Retail Federation (NRF).

The objectives of reverse logistics are to recoup value and ensure repeat customers. Savvy companies use reverse logistics to build customer loyalty and repeat business and to minimize losses related to returns.

Reverse Logistics vs. Traditional Logistics

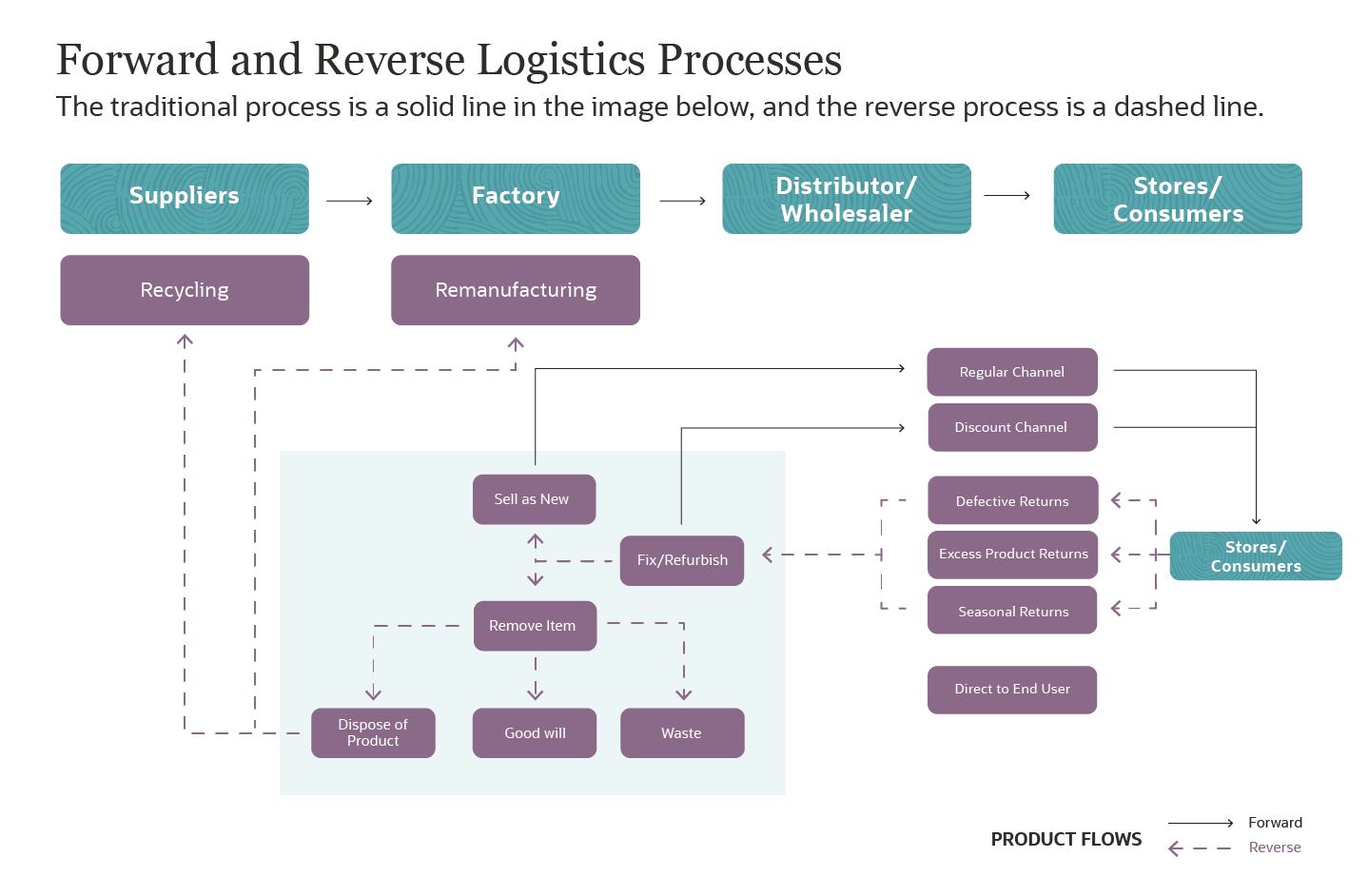

Traditional product flow starts with suppliers and moves on to a factory or distributor. From there, the goods go to retailers and customers. Reverse logistics management starts at the consumer and, moving in the opposite direction, returns products to any point along the supply chain.

Well-designed supply chains are responsive to changes and can handle some reverse logistics requirements. This reverse process can return products one step back in the chain or to the original supplier. They can even send returned products back to regular sales or discount channels (like liquidators).

Types of Reverse Logistics

The different types of reverse logistics are also known as reverse logistics components. They focus on returns management and return policies and procedures (RPP) and account for remanufacturing, packaging, unsold goods and delivery issues. Other types of reverse logistics account for leases, repairs and product retirement.

- Returns management: This process deals with product returns from customers or avoiding returns in the first place. These activities should be fast, controllable, visible and straightforward. Customers judge a company on its return flow and re-return policies. A re-return is the return of an item a second time. Often, these returns trigger the extended return policies, such as offering store credit. For example, a customer buys a returned product on clearance, takes it home and discovers it broken. The store policy would not normally accept the return, but it does allow for a store credit for the faulty product. A re-return can also occur when a vendor rejects the return and gives it back to the purchaser without a refund. This scenario could happen with custom-made items.

- Return policy and procedure (RPP): The policies about returns that a company shares with customers is its RPP. These policies should be visible and consistent. Employees should also adhere to them.

- Remanufacturing or refurbishment: Another type of reverse logistics management includes remanufacturing, refurbishing and reconditioning. These activities repair, rebuild and rework products. Companies recover interchangeable, reusable parts or materials from other products, also known as the cannibalization of parts. Reconditioning involves taking apart, cleaning and reassembling products.

- Packaging management: This type of reverse logistics focuses on reuse of packing materials to reduce waste and the disposal.

- Unsold goods: Reverse logistics for unsold goods handles returns from retailers to manufacturers or distributors. These types of returns can be due to poor sales, inventory obsolescence or a delivery refusal.

- End-of-life (EOL): When a product is EOL, it is no longer useful or does not work. The product may no longer meet a customer’s needs or be replaced by a newer, better version. Manufacturers often recycle or dispose of products that are end-of-life. These goods can create environmental challenges for manufacturers and countries.

- Delivery failure: With failed deliveries, drivers return products to sorting centers. From there, the sorting centers return the products to their point of origin. While rare, some sorting centers may have the staff available to identify why a delivery failed, correct the problem and resend.

- Rentals and leasing: When a piece of equipment comes to the end of its lease or rental contract, the company that owns the product can remarket, recycle or redeploy it.

- Repairs and maintenance: In some product agreements, customers and companies maintain equipment or repair it if issues arise. In some cases, the company sells damaged returned products to another consumer after repair.

The Reverse Logistics Process

The reverse logistics process involves managing returns and buying surplus goods and materials. The process is also responsible for dealing with any leases or refurbishments. Reverse logistics vary across different industries, and there are different economic incentives for improving reverse logistics management.

For example, in the beverage industry, the reverse logistics process uses empty tap containers. Beverage production companies want to recapture the value of their containers by reusing them. This requires planning transportation, managing shipping loads and cleaning the containers.

In the construction industry, reverse logistics moves and recycles salvaged materials to new sites. As the construction industry adopts more sustainable practices to reduce waste, there is an opportunity for cost savings by using reverse logistics.

In the food industry, reverse logistics is responsible for returning packaging materials and pallets. Companies also must deal with rejected food shipments. Rejections can create logistical challenges due to delays that lead to food spoilage and concerns over tampering. The Reverse Logistics Association (opens in new tab) is developing secure, quick, reliable, login (SQRL) codes on packaging to provide detailed product information and address these logistical challenges.

Generally, the reverse logistics process follows these five steps:

- Process the Return

The return process starts when the consumer signals they want to return a product. This step should include return authorization and identify the product’s condition. This process also involves scheduling return shipments, approving refunds and replacing faulty goods. - Identify the Return

Once a returned product arrives at your location or centralized processing center, inspect it and determine its return category. (Note: If you have optimized reverse logistics, you should know where the product should go before it arrives.) Sort products into the disposition options: fix, resell as new, resell as a return, recycle, scrap or refurbish. - Keep the Return in Motion

The less time any returned items spend in limbo, the more efficient and cost-effective reverse logistics will be. That means setting up the process so that the return is in constant motion toward its next stop. Products in need of repair should be sent straight to that department, for example, and those that can be recycled should be shuttled to the proper place. Moving returned items from point to point as quickly as possible maximizes capacity and reduces waste and wasted time. - Repair

Once the returned item or equipment is reviewed and deemed fixable, it can move to the repair department. If the product is not repairable, the company can sell any usable parts. - Recycle

Finally, parts or products that cannot be repaired, reused or resold should be assessed for recycling instead. Sustainability is a front-and-center priority for most organizations, so ensuring the proper recycling or disposal of caustic or otherwise potentially harmful parts (e.g., batteries and computer screens) will go a long way toward demonstrating environmental responsibility. Manufacturers and retailers can set up partnerships with recycling and disposal companies to handle this step in the process.

Video: What Is Reverse Logistics?

Reverse Logistics Performance: Measuring the Five “R’s”

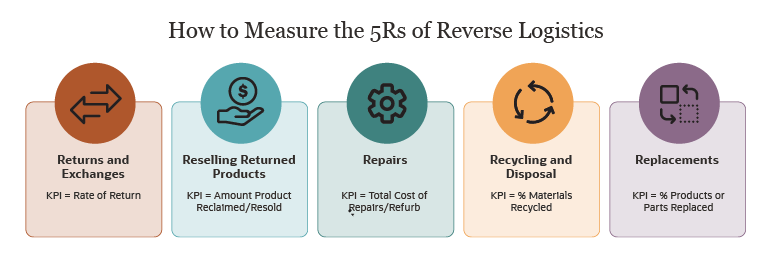

To evaluate the effectiveness of their return logistics practice, companies can establish performance metrics that align with each of the so-called five “R’s” of the process: returns and exchanges, repackaging and reselling, repairs, recycling and disposal, and replacements. By assigning key performance indicators (KPIs) to each one, companies can assess the success of their efforts, optimize what’s working and fix what’s not, with the ongoing goal of continuous improvement.

- Returns and exchanges: One key KPI for returns and exchanges is the return rate. While some returns are unavoidable (and stringent no-return policies can cause customers to balk), high return rates can be costly for a business. What’s more, it can be an indicator of product-quality issues or other sources of customer dissatisfaction, such as poor product descriptions or slow delivery times.

- Reselling and repackaging: A valuable KPI here is the percentage of returned products that can be repackaged and resold. While there is a cost to reverse logistics, the ability to resell a product helps offset the financial hit to the business.

- Repairs: Manufacturers and retailers can track the total cost of product repairs or refurbishment to ensure they do not become a money-losing proposition for the business. If the total cost is too high or trending higher, seek ways to streamline the process.

- Recycling and disposal: Companies are increasingly establishing goals or benchmarks for recycling and/or properly disposing of returned products or components. Tracking the percentage of returned materials that are recycled or properly handled is important to meet those goals.

- Replacements: Returned products that are defective may need to be replaced in part or in full.Tracking the percentage of products sold that require replacements can reveal product-quality issues that need to be addressed. Alternatively, there could be issues with user or shopper education about how to properly use or assemble an item that may not need to be replaced at all.

Importance of Reverse Logistics to Your Business

Reverse logistics is important because it maintains an efficient flow of goods. The process reduces costs, creates value, decreases risk and completes the product life cycle.

Gartner Research says that about 70% of businesses plan to invest in the "circular economy." This circular economy follows traditional logistics and then continues around through what Gartner calls a closed-loop supply chain.

With this practice, companies are participating in a system focused on a sustainable economy. Companies find new uses for disposed products with recovery, repair and recycling. Materials once typically viewed as waste have value again.

The circular economy also ensures compliance as many countries institute a policy requiring "producers" to develop more sustainable practices. The guidelines outline subsidies for waste prevention, research and development and recycling. Other policies restrict landfills, mandate collection and recycling programs, and penalize certain waste practices.

How Does the Reverse Logistics Process Create Value?

In 2022, U.S. consumers returned 14.5% of purchases, costing retailers an estimated $743 billion in lost revenue, according to the NRF. An effective reverse logistics process can help companies recoup some of those losses (or at least not add to them).

Reverse logistics creates value in multiple ways, first and foremost by building customer trust and satisfaction. With a robust reverse logistics process, businesses can also resell, reuse and recycle returned products, thereby transforming waste into future sales and fueling sustainability efforts. In addition, an effective reverse logistics practice minimizes storage and distribution costs.

As customer demand for high-quality products and easy returns has grown, it has fueled growth in this area. The global reverse logistics market size, valued at $768.59 billion in 2023, is projected to grow to $801.64 billion in 2024 and $1.17 trillion by 2032, according to Fortune Business Insights.

Using reverse logistics to boost the efficiency of the traditional supply chain benefits everyone. Some businesses separate their forward and reverse logistics, while others combine them. The relative success of combining them depends on the company’s experience, the value of its products and return volume. Either way, they use practices to maximize their profitability ratios with their supply chain activities. Read these expert tips on how to maximize profits in business.

Benefits of Optimized Reverse Logistics

Optimized reverse logistics produce financial benefits while positively impacting the environment and business culture. Refining the processes for what happens to products after delivery helps retain customers and save money.

The product data collected when engaging with customers after delivery is an advantage of well-executed reverse logistics. Data provides insight into an organization’s supply chain and an opportunity to improve products and/or the customer experience.

Optimized reverse logistics also leads to better supply chain visibility, which leads to benefits like:

- Cost reduction

- Greater customer satisfaction

- Better customer retention

- Faster and better service

- Loss reduction

- Improved brand sentiment

- Waste reduction and greater sustainability

Challenges of Reverse Logistics

A challenge of reverse logistics is that the flow must be bi-directional. Managers need to set up the right infrastructure for it to be effective. That often requires software that can automate and track every step of reverse logistics. Additionally, once that infrastructure is in place, management needs to continually monitor and evaluate the organization’s reverse logistics processes to ensure efficiency.

Companies must track inbound and outbound logistics to get the full picture. Inbound logistics manages the receipt of raw materials or goods from the supplier to the manufacturer. Outbound logistics oversees the delivery of finished goods to the end user. Both inbound and outbound logistics are measured from the manufacturer’s perspective, while reverse logistics can be part of any point in the supply chain.

7 Strategies to Optimize Reverse Logistics

To optimize reverse logistics, companies need cohesive strategies that account for speed, efficiency and cost. When taking action, consider policies, partners, data, capacity, logistics and transportation.

Here are seven strategies to optimize reverse logistics operations:

- Evaluate relevant policies and agreements: Review and revise the procedures related to your company’s returns and repairs. These policies should be clear and consider the root causes of returns and repairs. The way a company deals with returns and repairs can be competitive differentiators.

- Collaborate with suppliers: Close collaboration with suppliers can help ensure a smooth, integrated experience for customers, not a disjointed one they will struggle to navigate.

- Use data to optimize processes: By collecting data on product returns, you can understand why customers may be returning products. Then, you can make adjustments in sales, product design and forward logistics processes accordingly.

- Track products forward and backwards: Linking raw materials to the finished good and the customer order allows you to trace ingredients in the event that you need to process recalls—instead of issuing them for entire lines, you can find the issue and selectively issue recalls.

- Centralize return centers: With a centralized return center, you can better sort products and identify the best next step for each of them. With a center, businesses can more efficiently determine how best to reclaim product value. If your company lacks the resources to have a separate returns center, consider dedicating a portion of your warehouse or factory to returns.

- Examine logistics and transportation: Regularly review the processes for forward and reverse logistics and transportation. Determine if it is feasible to integrate some of these processes and transit. For example, if your delivery drivers can pick up empty pallets as they drop off full pallets, you save trips, time and money.

- Automate: Use cloud-based logistics software to help streamline operations. For example, a software system can track asset recovery, manage refurbishment and provide business intelligence analytics.

How Does Reverse Logistics Impact Supply Chain Management?

Reverse logistics provide another critical opportunity for supply chain optimization. Supply chain management accounts for the reverse and forward flow of goods, and a surge of returns can drive up supply chain costs, harming profitability.

What Is Reverse Logistics vs. Reverse Supply Chain?

The reverse supply chain is the backward movement of goods (such as defective products) from vendors back up the supply chain. It is the opposite of the typical supply chain, where items go from manufacturer to retailer to consumer.

Reverse logistics refers to everything related to returns and what happens to those products after the consumer takes them back. That includes planning and implementing strategies to reduce costs and losses related to returns and to build a better returns experience.

Monitoring Reverse Logistics in Your Supply Chain

Companies monitor reverse logistics in the supply chain to find better ways to process and dispose of products. There is a considerable amount of information available in the ways goods move back and forth through the supply chain. This detail can help companies meet their delivery goals.

Some organizations have the simple goal of on-time delivery; others reach for what they call the "perfect order.” For every order, the goal is to get a perfect score in place, time, condition, package, quantity, documentation, customer and invoice. The only way to achieve a perfect order is to monitor the data, develop metric targets and improve processes based on your results. Reverse logistics can play a central role in delivering the perfect order.

5 Key Reverse Logistics Supply Chain Metrics to Monitor

There are five key reverse logistics-focused supply chain metrics that will help increase asset recovery. Supply chain analytics can help management make data-driven decisions at all steps of the supply chain.

- Volume: The volume of products returned and subsequently resold, reused and recycled is a top metric used to track reverse logistics. Companies should use these measurements to identify missed opportunities or problems and determine where process improvements can make a difference.

- Percent of costs: Compare the costs attributed to resales, refurbishing, reuse and recycling to the total supply chain cost. Determine the difference in the price of these activities versus the cost of returns. Be sure to calculate the percent of expenses recovered by item.

- Condition of returned products: Some products come back in perfect resale condition, and companies can turn them around for resale at full value. Other goods may need some work before a company can resell them. In that scenario, companies should consider other sales channels for those products. For example, companies may sell refurbished electronics through another sales channel. Determine the cost of materials and workmanship to determine the full value. Review the percent of items sent to each sales channel and whether the company is recouping enough money.

- Financial value: Each part of the supply chain has economic value. Understanding what financial stake your company has in each step can lead to better processes and efficiencies.

- Errors: Every step in the supply chain also has the potential for errors, such as unaccepted deliveries or defective materials. Review the cost of mistakes and how frequently they occur to identify opportunities for improvement.

Supply chain analytics should exist throughout the entire value chain, from sourcing materials through distribution and delivery. Useful metrics lead to growth in revenue, better margins and controlled capital. Supply chains are increasingly going digital, so collecting the data is easier. Read the supply chain analytics guide to learn how to make the most of this practice.

Reverse Logistics Examples

Globally, companies are changing the ways they address waste, and how they manage their supply chains is a big piece of those initiatives. In addition, meeting customer expectations for the effective handling of returns, exchanges, replacements and recycling is increasingly a necessity for most companies.

One of the best ways to understand the benefits of incorporating returns, exchanges and recycling into the supply chain process is to examine some successful implementations.

- Easing the pain of online returns: People are more likely to buy products from a company if returns are easy to make, and they are even more likely to become repeat customers if they’ve had a good return experience. Recognizing this expectation particularly for online shoppers, Home Depot offers its customers reverse logistics help for ecommerce purchases. The company’s online sales grew from 10% of all sales in 2019 to 14.8% in 2023, and they continue to climb in 2024. When a customer wants to return goods, they are given a choice to either send them back by printing a shipping label or to drop them off in-store. These items are then sent to Home Depot’s reverse logistics centers, which also handle damaged and misdirected products and work to ensure materials are recycled. This includes typically recycled metals, hard plastics, and shrink wrap, as well as EPS foam packaging and CFCs from appliances.

- Boosting sustainability: Clothing manufacturer and retailer Levi Strauss uses reverse logistics to improve sustainability in textiles. The business repurposes jeans or recovers and reprocesses the fibers into raw materials to make new jeans. By partnering with other companies for repurposing, Levi Strauss can produce reconstructed jeans at a higher price point.

- Integrating in-person returns: Kohl’s, a major retailer with close to 1,200 brick-and-mortar stores, is another example of the reverse supply chain in action. The company recently introduced The Return Drop at more than 1,100 of its U.S. locations. After initiating the returns process, shoppers can choose “Kohl’s Drop Off” and receive a QR code to bring in with the return to a local Kohl’s location — no box or shipping label required. Kohl’s had also extended its partnership with Amazon to accept, screen and send back Amazon returns in a single shipment. Customers who prefer returning products in-person benefit from this relationship, and Kohl’s gets a boost in foot traffic from customers who may not otherwise make a trip to its stores.

- Whittling away at waste: Some brands are also turning to reverse logistics to address waste, exploring the use of reusable packaging that consumers can return or refill. The companies will clean and use the containers again — or refill them for customers. PepsiCo, for example, declared a global packaging objective in 2022 to increase the proportion of beverage servings it sells that are supplied in refillable models from 10% to 20% by 2030. Nestlé announced plans to make all of its packaging reusable or recyclable by 2025 (87% of its packaging is already recyclable or refillable). Some recent investments in this area include the introduction of a refillable pet food system in Chile.

- Embracing recommerce: Some companies, such as GE Healthcare and Cisco, have for some time specialized in refurbishing, repairing and remanufacturing defective or end-of-life goods for buyers. Cisco refurbishes and resells goods, such as phones, routers and switches, while GE Healthcare does the same for imaging devices and ultrasound machines. Business consultancy Baufest says this so-called “recommerce” trend is on the rise, due, in part, to an increased focus on social and environmental responsibility. It also enables companies to maximize the lifetime value of their products by reselling them after “reconditioning and value enhancement.”

Find more examples of how companies are making returns work for them with reverse logistics.

The Future of Reverse Logistics

The future of reverse logistics is all about minimizing disruptions from an increasing volume of returns, especially in ecommerce, where it is expected to reach $931.85 billion in the U.S. in 2024 and $1 trillion by 2027, according to eMarketer. At the same time, customers expect a straightforward and simple returns process. Call it the Amazon effect, but shoppers will walk away from unfriendly return policies: Approximately eight in 10 U.S. adult digital shoppers said they review return policies before making a first-time purchase, and more than half (55%) will abandon their carts if return policies aren’t convenient, according to a Happy Returns report commissioned by PayPal.

Looking ahead, several trends could further increase the business value of reverse logistics investments. Companies that invest in data and systems integration will be able to more tightly integrate their reverse logistics processes into their logistics operations and optimize delivery routes. A variety of newer technologies, like artificial intelligence and robotics, is likely to drive greater automation and efficiency throughout the reverse logistics process, from streamlining warehouse operations, to increasing product traceability and visibility, to even predicting how return and exchange activity is likely to ebb and flow. As previously mentioned, recommerce — or reselling returned products — is also likely to grow in popularity. Finally, the focus is likely to increase on evolving reverse logistics from a cost to minimize to a potential source of business revenue, with a focus on increasing efficiency, automation and resales.

Manage Reverse Logistics with Warehouse Management Software

Managing your reverse logistics is essential for the bottom line and reputation of your business. Consumers need to feel like they are buying products from companies with integrity, and improving your reverse logistics opens up opportunities for a number of sustainable business practices.

That’s why it is crucial to have a warehouse management system (WMS) that can manage inbound and outbound logistics and deliver analytics in real time. Businesses need insights across transportation and logistics providers, through warehouse and fulfillment and ultimately need to integrate all that information with financial data in an enterprise resource planning (ERP) system. ERP platforms like NetSuite, paired with a warehouse management system, allow companies to easily track returns, monitor the movement of goods, issue credits through the accounting system and update everything in the customer record.

Similarly, inventory management is key to efficient returns processes. A high rate of returns can lead to inventory buildup, and an effective inventory management system will alert you when inventory levels are growing too quickly—faster than your rate of sales.

Many companies are taking a closer look at their reverse logistics as they realize returns are a major source of expenses and there are opportunities to recover more money on those goods. Additionally, rising return rates make it imperative for these businesses to figure out a more cost-effective way to handle products sent back to them. Evaluating your reverse logistics processes to identify inefficiencies and address those shortcomings can boost your bottom line by not only lowering costs but increasing customer loyalty and elevating brand reputation.

Award Winning

Cloud Inventory

Reverse Logistics FAQ

You may have additional questions about reverse logistics. Below, we answer some of the most popular ones.

What is integrated logistics?

Integrated logistics is the full process that covers delivery through end-user issues and then deals with product disposition. Integrated logistics stresses material and resource sustainability.

How much does it cost to implement a reverse logistics plan?

Implementing a reverse logistics plan costs about 7-10% of the cost of goods in a company. However, it’s worth noting that reverse logistics planning should bring down the costs associated with returns.

How does reverse logistics work in the pharmaceutical industry?

In the pharmaceutical industry, reverse logistics helps keep medicines safe (out of landfills and water supplies). The sector handles product returns and disposal through third-party companies and distributors.

Can you explain the role of reverse logistics in the service industry?

In the service industry, reverse logistics helps address repairs more quickly. Best practices include refunds, warranty work and credit. Working out these policies keeps customers happy.

How does reverse logistics differ for the manufacturing and service industries?

The service and manufacturing industries differ from others. Their products and services are not standard, so the returns are not standard. The reverse logistics process starts after the company fixes the service or manufacturing part.

Manufacturing companies sell fixed parts as refurbished items. These parts have a lower value and may go through a different supply chain. In the service industry, companies can provide warranty work, credit, or work refunds.

How can ecommerce organizations handle reverse logistics to ensure it’s a low-cost transaction?

To make returns a low-cost transaction, ecommerce companies should combine returns with deliveries. They should also consider turning to third-party partners. Ecommerce businesses should identify the root causes of problems and develop strategies to decrease these issues.

What is a reverse logistics expert?

A reverse logistics expert is a professional who can help your company be more efficient by suggesting and implementing process improvements in your reverse supply chain. Good reverse logistics experts consider your customers, business priorities and sales goals.

How are forward logistics and reverse logistics different?

The difference between reverse and forward logistics is the direction the product is moving along the supply chain. Products that come from the manufacturer and move toward the customer are going forward. Products coming back from customers to retailers or manufacturers are heading in reverse.

What is reverse distribution?

Reverse distribution is the role of removing goods that are unsold, damaged, expired or recalled from retailers. Like with returns, these goods go in the reverse direction through the supply chain.

What is design for logistics (DFL)?

The concept of DFL states that products and their packaging design can lower the expenses related to logistics. For example, soda cans became flat on top, making them easier and cheaper to transport and store.

What is design for reverse logistics (DFRL)?

DFRL refers to designing products and packaging that makes it cheaper and easier to move in a reverse flow in the supply chain. For example, manufacturers package products in reusable canisters that they refill for retailers.

How does reverse logistics reduce business risk?

Reverse logistics reduce business risk by ensuring companies adhere to policies for waste and disposal. Some governments fine companies that do not meet guidelines. Reverse logistics also help companies recoup value in unsold and returned goods.

How do you lower the cost of reverse logistics?

Cut the costs in reverse logistics by first decreasing returns. Experts recommend enabling customer product reviews to help set expectations and reduce returns. Then, look for ways to combine reverse and forward logistics to drive cost savings.

How does reverse logistics contribute to a lean supply chain?

A solid reverse logistics plan reduces waste. Lean principles can also make the supply chain more efficient. Instead of separating shipping and returns, a lean supply chain combines them.

How does reverse logistics work?

Reverse logistics moves goods from the traditional endpoint of the supply chain at least one step backward. This process can involve various plans and controls. Some companies prefer to outsource this work.